Contact Conveyor Maintenance Services In Innisfail

Conveyor Belt Services That Keep Your Operation on Track

Innisfail Conveyor Belts

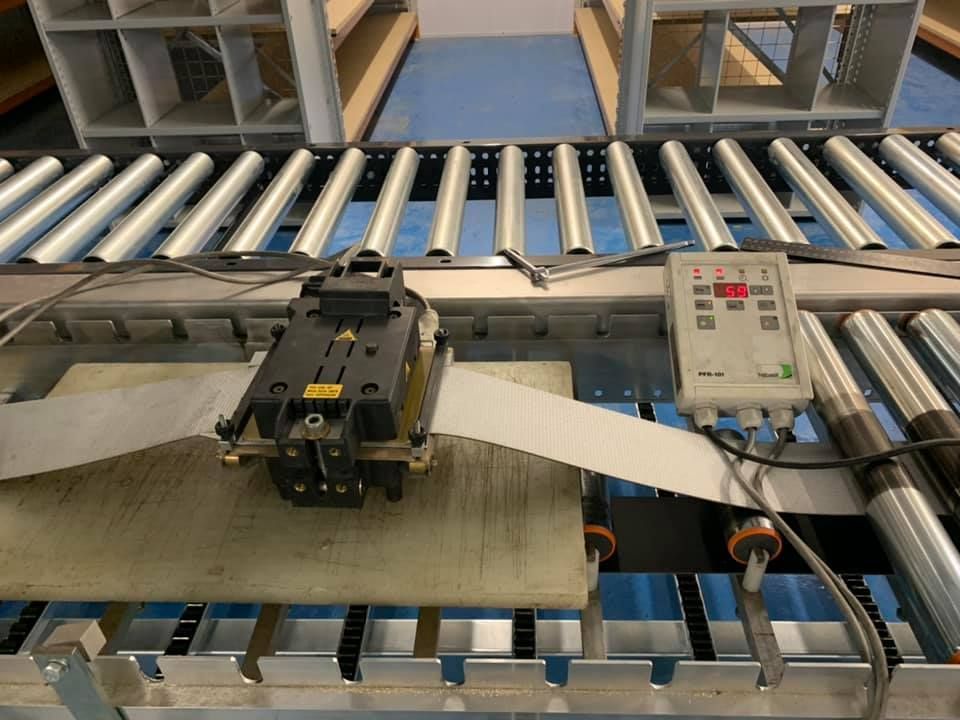

Conveyor Maintenance Services supports industries in Innisfail with fast, efficient conveyor belt services tailored to local operating conditions. From wet-season wear to high-output production lines, we understand the challenges regional businesses face when it comes to keeping systems running reliably.

We carry a wide range of conveyor belts, including PVC, rubber, solid woven and steel cord, alongside essential parts like rollers, belt cleaners and skirting. Whether you're setting up a new system or replacing worn components, we can customise a solution to suit your load, site layout and output requirements.

Our services include:

- Hot Vulcanising

- Splicing

- Pulley Lagging

- Preventative Maintenance

With over 20 years of industry experience and ISO9001 certification, our team provides the trade-level support and practical advice your business needs. We’re quick to respond, easy to deal with, and focused on long-term performance.

Call Conveyor Maintenance Services on 07 4774 3177 today!

Conveyor Support for Local Industry

What We Provide

We supply conveyor products for operations in Innisfail, including belting, rollers, skirting and cleaners—designed to handle moisture, wear and the demands of busy production and processing environments.

Conveyor services in Innisfail include splicing, lagging, maintenance and on-site repairs. We work quickly and safely to reduce disruption and help extend the life of your equipment.

We install and maintain conveyor belts across Innisfail, matching each system to your material type, flow rate and equipment layout for smoother operation and better reliability.

Prompt Service, Proven Products, No-Fuss Results

Why Our Clients Rely On Us

Here are just a few reasons Innisfail operators turn to us for conveyor belt support:

- Real-World Experience: We’ve spent decades working in the field—on farms, in processing sheds and on commercial sites—so we know what conveyor systems go through and how to keep them running.

- End-To-End Service: From the first call to the final belt check, we handle everything in-house. That includes splicing, lagging, preventative maintenance and complete new belt installations.

- Fit-For-Purpose Products: Our belt materials are chosen for long-term performance in wet, high-wear or high-output environments. We supply everything from food-safe PVC to solid woven and rubber belts.

- Flexible, On-Site Support: Our crew comes to you, fully equipped to assess and repair belts on the spot. That means fewer hold-ups and faster turnaround when things go wrong.

- Trade-Focused Reliability: We’re here to get the job done, not just talk about it. Clients value our straight-up communication, consistent results and practical advice that helps prevent future downtime.

Contact Conveyor Maintenance Services In Innisfail

Phone

Location

Business Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed