Wide Range of Conveyer Belts in Townsville

Wide Range of Conveyer Belts

Conveyer Maintenance Services is proud to offer a wide range of conveyer belts, including multi-ply, steel cord, rip stop, auto-stable, sidewall, chevron and profile and feeder options. Our knowledgeable team can help you choose the right conveyer belt for your requirements, whether you're after a PVC/PU lightweight option or a conveyer belt suitable for a specific industry, such as the sugar industry.

To learn more or request a quote, call

07 4774 3177 today. We're based in Townsville but service

Mount Isa,

Charters Towers,

Proserpine,

Mareeba and surrounding regions.

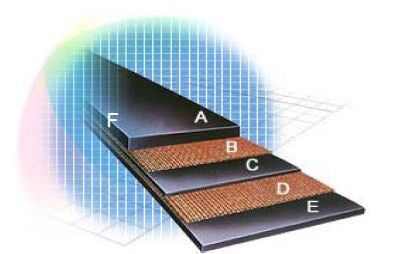

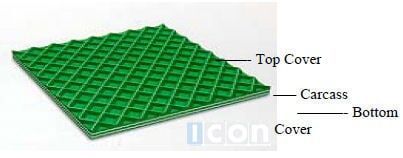

Multi-Ply Conveyor Belt

Applications

- Surface & Underground Mining

- Quarries & Sandpits

- Iron & Steel Industry

- Harbour & Port Installations

- Thermal Power Plants

- Timber & Paper Industry

- Agriculture Industry

- General Conveying

- Cement Works

Features

- Polyester Nylon (PN or EP)

- Synthetic woven fabric, with polyester fibre in the warp and nylon fibre in the weft

- Medium, long distance & heavy load transportation of materials

- Low elongation and good troughability

A. Top Cover: Various thicknesses and grades available

B/D. Carcass: From 1 ply to multiple plies

C. Skims: From 0.5mm upwards

E. Bottom Cover: Various Thicknesses and grades available. Bare back also available.

F. Moulded Edge (Sealed) or Cut Edge

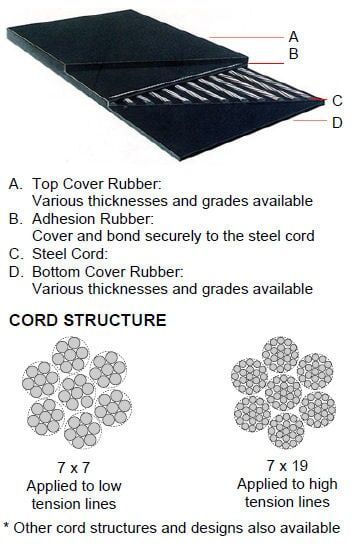

Steel Cord Conveyor Belt

Features

- Suitable for large capacity loads over long distances at high speeds

- High tensile strengths available

- Low elongation with less take-up required

- Excellent trough ability & flexibility

- Excellent spicing efficiency

- Manufactured to AS1333 or DIN standards

Applications

- Port & Harbour Installations

- Overland & Steep Conveyors

- Surface & Underground Mining

- Thermal Power Stations

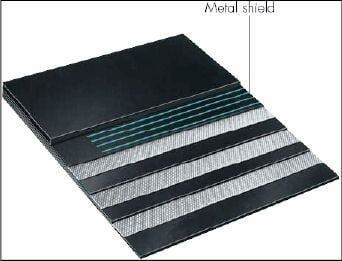

Rip Stop Conveyor Belt

Features

- Anti-tear & rip-resistant qualities without any equivalent in conventional fabric conveyor belts

- Special Steel wefts with high elongation & tensile strength properties arranged at a nominal pitch:

- To break the ripping momentum, limiting any longitudinal cutting and tearing

- To eject foreign bodies that have penetrated

- Trip-out overload setting to contain any damage

- Superior carcass protection through greater impact energy distribution across the belt width

- Exceptional fastener-holding ability if required

- Pulley system modifications not required; transversal steel weft has no influence

- Longer service life under heavy duty applications

- Manufactured to AS1332 or DIN standards

Applications

- Quarries & Sand Pits

- Hard Rock Mining & Surface Applications

- Raw Coal Applications & Processing

- Cement Works

- Thermal Power Stations

- Forestry & Timber Works

- Iron & Steel Industry

- Harbour & Port Installations

Auto-Stable Conveyor

Features

- Offering instantaneous self-centring, which provides stability of the belt along the length of the system

- Elimination of systematic pinching, hence less wear & lower friction (reduced power consumption), as well as reduced belt edge damage & increased belt life

- Increase in output owing to stabilisation of the vein & slope of the product, with the possibility of increasing the troughing angle to optimise volumetric capacity

- No need for external tracking accessories or conveyor modifications for belt training of misalignment issues

- Exceptional fastener-holding ability in an emergency shutdown

- The added advantage of the steel weft providing greater impact energy absorption across the belt width, as well as the width of steel weft at a nominal pitch providing rip/tear protection in steel carcass belts

- Manufactured to AS and/or DIN / ISO standards

Applications

- Bulk Handling Operations & Terminal Seaports

- Various Mining Operations (ores, coal, phosphates, etc.)

- Cement Works & Quarries

- Thermal Power Stations

- Forestry & Timber Works

- Iron & Steel Industry

- Reversible Installations (ship loaders, stacker/reclaimers)

- Installations with Poorly Centred Loads (bucket wheels)

- Conveyors with Curves in the Horizontal Plane

- Special Applications

Sidewall Conveyor Belts

Sidewall Features

- Wave design ensures maximum flexing without fatigue

- Profile has excellent vertical stability for load retention & return side support

- Vulcanised from both sides, giving superior bond strengths to the base belt

- Fabric reinforcement provides excellent tear resistance & stability for deeper profiles (>200mm high)

- Rubber compound has high abrasion resistance & high tensile strength

- Supplied hot vulcanised onto base belt, or supplied loose on demand

System Advantages

- Minimal spillage with steep angle & vertical conveying

- Cross cleats prevent product fall back

- No wearing from side skirts

- No transfer points from the feed hopper to discharge point with multiple turning angles, thus reducing dust & pollution

- Maximum utilisation of space, with the ability to convey material at up to 90-degree angles

- Minimum maintenance & longer belt service life

- A wide range of materials can be handled

- Low power requirements & quiet smooth running

- Sidewall, Cross Cleats & Base Belt are all hot vulcanised together, providing high strength & extended belt life

Chevron & Profile Conveyor Belts

Features

- Excellent choice for high capacity conveying at steep angles to prevent load slip or product rollback

- Cleats integrally moulded with the top cover rubber, preventing separation from the belt

- A large range of designs & patterns available

- Cleats with high abrasion resistance & elastic rubber compounds for flexibility

- Various cleat heights & widths available, depending on the application requirements

Applications

- Wood Chips

- Sand & Gravel

- Heavy Duty Scrap Metal

- Minerals—Coal & Ore

- Materials—Fine Coal & Grains

- Waste & Recycling Plants

- Road Construction

- Bagged Materials

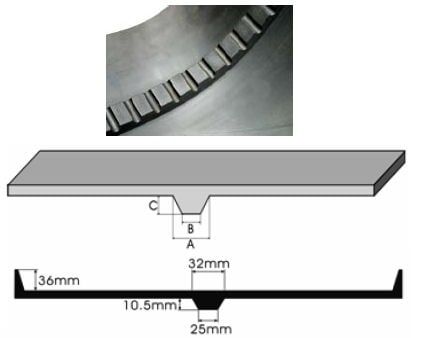

Feeder Conveyor Belt

Flanged Conveyor Belt

Features

- Specialty belts used for coal-burning applications, power stations, cogeneration plants & cement manufacturing

- Belt construction & flanges are integrally moulded & hot vulcanised

- Option to include V-guide tracking strip that fits into a groove on the pulleys, reducing tracking problems

Benefits

- Flanged structure prevents coal powder or lumps from spilling over edges during transportation

- Notching design enables operation in smaller pulley diameters

- Easily mechanically fastened

V-Guided Conveyor Belt

Features

- Designed to keep belts running consistently in the proper alignment

- Tracking profile is integrally moulded with the cover rubber, preventing separation from the belt

- Option to include flanged edge structure

Benefits

- Reduces tracking problems

- Reduced edge wear & belt maintenance

- Reduced spillage & longer belt life

- Easily mechanically fastened

Industries / Applications

- Coal Fired Power Plants

- Utilities

- Cogeneration Plants

- Industrial

- Mining Industry

- Cement & Manufacturing Plants

- Recycling Industry

- Steel Producers

- Manufactured to AS or DIN standards

PVC & PU Lightweight Conveyor Belts

Features

- Conveyor & processing belts for light & medium duty applications in both industrial & service industries

- Robust & longitudinally flexible

- Lightweight with low overall thickness

- Low elongation

- Monofilament fabric with a low coefficient of friction

- FDA-approved for conveying floor products with resistance to oils, fats, chemicals & grease

Applications

- Sheet Metal Processing & Automobile Industry

- Distribution Centres & Airports

- Marble & Brick Industry

- Tobacco Industry

- Food Handling Industry

- Fish & Fruit Processing

- Wood & Chipboard Industry

- Packaging & Paper Industry

Sugar Industry Conveyor Belts

Features

- Conveyor belting designed to provide the sugar industry with cost-effective options depending on the nature of the application & product requirements

- Range suitable for handling cane, bagasse, reject materials & variations of processed sugar

- Self-extinguishing & anti-static compound grades

- Low elongation & good troughability

- Higher resistance to heat & moisture

- Medium, long-distance & heavy-load transportation of materials